Highlights

Fig. 1

K. Cheng, W. Chen, D. Liu, L. Zhang*, Y. Du, Analysis of the Cermak–Rothova method for determining the concentration dependence of ternary interdiffusion coefficients with a single diffusion couple, Scripta Materialia, 76 (2014) 5-8.

W. Chen, L. Zhang*, Y. Du, C. Tang, B. Huang, A pragmatic method to determine the composition-dependentinterdiffusivities in ternary systems by using a single diffusion couple, Scripta Materialia, 90-91 (2014) 53-56.

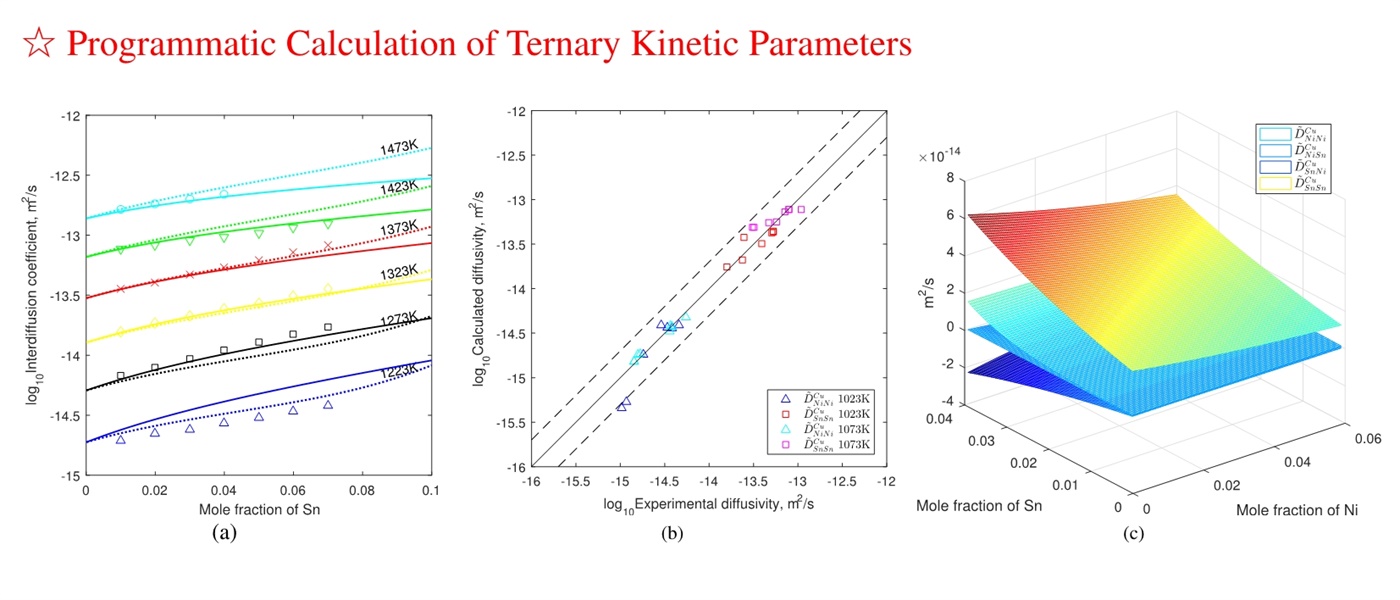

Abstract:Dayananda’s method for evaluating the average ternary interdiffusion coefficient by means of a single diffusion couple was extended by Cermak and Rothova to determine the composition-dependent interdiffusion coefficients in ternary systems. However, we argued that the so-called Cermak-Rothova approach could not be used to obtain the "truly" composition-dependent in terms of mathematical and physical considerations. Thus, a pragmatic method for determining the composition-dependent interdiffusivities in ternary systems by means of a single diffusion couple was developed and realized via a homemade code. Its reliability was further validated in a series of ternary diffusion couples by comparing with the results via the traditional Matano-Kirkaldy method.

Fig. 2

Na Ta, Lijun Zhang*, Yong Du, Design of the precipitation process for Ni-Al alloys with optimal mechanical properties: a phase-field study, Metall. Mater. Trans. A 45 (2014) 1787-1802.

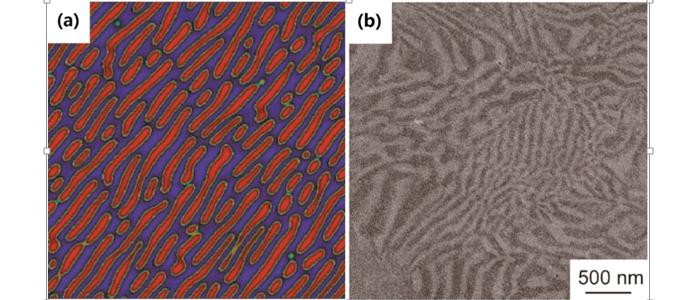

Abstract: Phase-field method has become an important and extremely versatile technique for simulating microstructure evolution at the mesoscale for the past decades. By coupling to the reliable CALPHAD (CALculation of PHAse Diagram) thermodynamic and atomic mobility databases, two-/three-dimensional quantitative phase-field simulations of microstructure evolution in the target alloys during various phase transformation processes become feasible. Different examples, including solidification process in commercial Al alloys, spinodal decomposition in Ag-Cu alloys, aging process in Ni-based super alloys, and interdiffusion process of Ni-Al-Cr bond coat/substrate systems during service, are presented here for a vivid demonstration of the powerful phase-field simulation. The reproduction of microstructure evolution during various materials processes can provide thorough guidance for material design and industrial production.

Fig. 3

W.B. Zhang, Y. Du*, W.M. Chen, Y.B. Peng, P. Zhou, S.Q. Wang, G.H. Wen, W. Xie, CSUDDCC1─A diffusion database for multicomponent cemented carbides, Int. J. Refract. Met. Hard Mater., 43 (2014) 164-180.

Abstract:

Effect of low nitrogen pressure on the formation of gradient zones in WC–Ti(C,N)–Co cemented carbides was investigated via experimental study and computer simulations. The sample with same composition are sintered at 1450 ℃ for 1 h under 0, 10, 20, 30 and 40 mbar nitrogen gas pressures. Comparing the micrographs (Fig. 1(a)) of the cross section of the cemented carbides sintered under different low nitrogen gas pressure shows that a decreasing thickness of fcc-free surface layers with increasing nitrogen gas pressure. Based on the thermodynamic and diffusion databases, the gradient zone formation of the cemented carbides is simulated by DICTRA software, and compared with the experimental results. As can be seen in Fig. 1(b), the thermodynamic and diffusion databases can reasonably reproduce most of the experimental concentration profiles.

Fig. 4

Y. Peng, Y. Du, P. Zhou, et al., CSUTDCC1-A thermodynamic database for multicomponent cemented carbides, Int. J. Ref. Met. Hard Mater., 42 (2014) 57-70.

Abstract: A thermodynamic database for multicomponent C-W-Co-Fe-Ni-Cr-V-Ti-Ta-Nb-Zr-N cemented carbides has been established. On the basis of the thermodynamic simulations, the thermodynamic database can be used to solve various technical problems and guide the development of new cemented carbides. Figure 1 gives a represent example of developing new cemented carbides with the presence of miscibility gap in the cubic phase, which can significantly improve the properties due to fine-grain strengthening.

Fig. 5

K. Li, A. Béché, M. Song, G. Sha, X. Lu, K. Zhang, Y. Du*, S.P. Ringer, D. Schryvers, Atomistic structure of Cu-containing β" precipitates in an Al–Mg–Si–Cu alloy, Scripta Mater., 75 (2014) 86-89.

Abstract: The β" precipitates in a peak-aged Al-Mg-Si-Cu alloy were measured with an average composition of 28.6Al-38.7Mg-26.5Si-5.17Cu (atomic percent) by using atom probe tomography. High-angle annular dark-field observations revealed that Cu incompletely substitutes for the Mg1 and Si3 columns, preferentially for one column in each pair of Si3. Cu-free Si columns form a parallelogram-shaped network constituting the basis of subsequent precipitates in the system, with a = 0.37 nm, b = 0.38 nm, γ = 113o and c = 0.405 nm.

Fig. 6

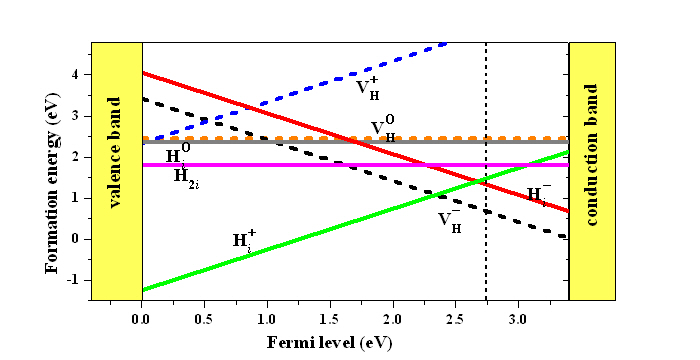

Jianchuan Wang, Yong Du, Honghui Xu, et al., Native defects in LiNH2: A first-principles study. Phys. Rev. B, 84: 024107 (2011).

Abstract: Native defects in LiNH2 are investigated by first-principles calculations based on density functional theory. We examine the structural properties and formation energies of H-, Li- and N-related defects in all possible states. We find that the dominant H- and Li-related defects are in charged states. Migration processes of the dominant defects are investigated. Both the formation and migration energies of Li-related dominant defects are found to be lower than those of H-related dominant defects. Having an activation energy of 0.72 eV, VLiˉ is the major diffusive species in LiNH2. Our investigation further indicate that the formation of H interstitial is the bottleneck for H transport.

Fig. 7

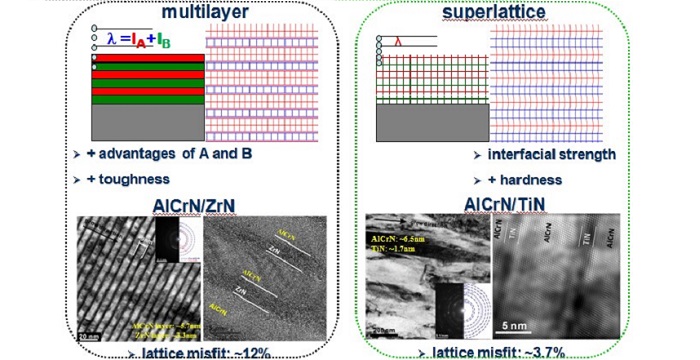

Li Chen, et al. unpublished (2014).

Abstract: Cr-Al-N coatings with cubic NaCl structure where Al substitutes for Cr

in the CrN based lattice (i.e., Cr1-xAlxN) have been used for wear protection in a wide variety of applications ranging from cutting tools to mechanical components in the aerospace industry due to their high hardness and wear resistance, together with good thermal stability, and oxidation resistance. In order to further improve the properties of Cr-Al-N coatings, CrAlN/ZrN and CrAlN/TiN multilayer coatings were deposited where multilayer structure provide a excellent alternative as these structures allow combining different materials selected to tailor the properties of the coating towards the application. According to the results of TEM and HRTEM, the CrAlN/ZrN coating exhibits a non-coherent interface due to large lattice misfit whereas a coherent interface is observed by the CrAlN/TiN coating.

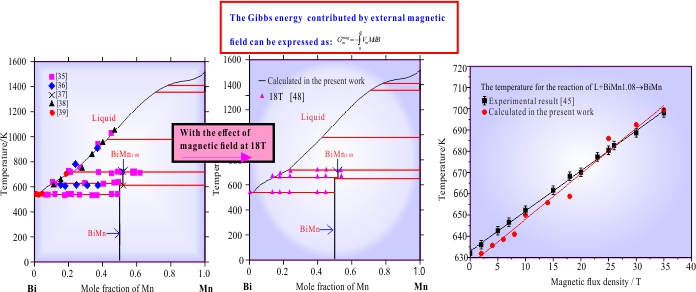

1.1 Phase Diagram and Thermodynamics

The Al-Fe-Ni-Si quaternary system is of critical importance to aluminum industry since many commercial Al alloys contain Fe, Ni, and Si as impurities or alloying elements. However, information on phase equilibria and solidification behavior in the Al-rich corner of this quaternary system is rather limited in the literature. Using a hybrid approach of experiment (XRD, SEM, EPMA, DTA, TEM) and thermodynamic modeling, a self-consistent thermodynamic parameters for the Al-rich corner of the quaternary system were obtained. This permitted construction of a full map of phase equilibria and thermodynamic properties of the quaternary system over the targeted composition and temperature ranges It was found that Al8Fe2Si particles embedded in the (Al) matrix during solidification are of nano-scale. In order to capture the nano-size particles in as-cast samples, TEM was employed, which provides high resolution electron microscopy images of the nanosized particles at high magnification. Fast fourier transformation (FFT) patterns of the nanoparticles were derived and indexed to determine their crystal structure. Results from Gulliver-Scheil simulations were also compared with experimental microstructures of as-cast alloys. The simulations agree well with the experimental observations based on XRD, SEM and TEM. This would not have been possible if only results from XRD and SEM were used. This paper has been published in J. Mater. Sci.

1.2 Diffusion Kinetics

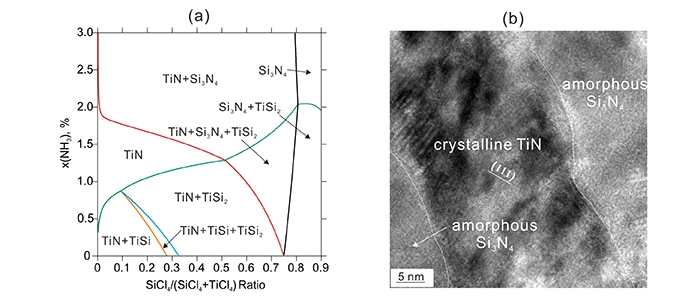

High-throughput determination of accurate diffusion coefficients in ternary or even higher-order multicomponent alloys has been a challenge for diffusion kinetics field for a long time. The traditional Matano-Kirkaldy method can result in reasonable diffusion coefficients, but two diffusion couples of which the diffusion paths intersect at one point are generally required, and only diffusion coefficients at the intersection point can be determined. Thus, the Matano-Kirkaldy method is of low efficiency. In 2003, the Dayananda’s method for evaluating the average ternary interdiffusion coefficient by means of a single diffusion couple was extended by Cermak and Rothova to determine the composition-dependent interdiffusion coefficients in ternary systems. The named Cermak-Rothova method has been published in Acta Mater., a well-known journal in the materials community.

However, in terms of Fick's law, we deduced the differential form of the Cermak-Rothova method, and argued that the Cermak-Rothova approach could not be used to obtain the "truly" composition-dependent in terms of mathematical and physical considerations. Moreover, based on Fick's second law, a pragmatic method for determining the composition-dependent interdiffusivities in ternary systems by means of a single diffusion couple was developed in our group and realized via a homemade code. In addition, another advanced feature of the new method isthat it can be easily extended to evaluate the composition-dependent diffusion coefficients in higher-order systems. Our results have been published as two papers in Scripta Mater., also a well-known journal in the materials community.

1.3 Atomistic Simulation

Combining nanometer to micrometer simulation techniques, multi-scale calculation can be directly used to study the macroscopic mechanical properties of materials.Recently, we use molecular dynamics and finite element method to investigate the Al/Pd multilayer thin films.The finite element method is employed to simulate indentation with a 100 nm spherical indenter on Al/Pd multilayer thin films and Al and Pd monolayer thin films. The elastic/plastic properties of bulk Al and Pd and the material formulation are obtained by molecular dynamics simulations of tensile and indentation loadings. Hill’s plasticity with isotropic hardening is found to best represent the stress-strain response of both bulk Al and Pd. The Pd monolayers appear the hardest and the Al monolayers the softest. The indentation hardness of both monolayered and multilayered films is found to increase with the indentation depth and appears independent of the layer order and thickness in the multilayers films. The hardness values determined by the finite element method simulations are close to those obtained using the well-known formula of Field and Swain. No hardness enhancement in very thin multilayered films (3 to 5 nm per layer) is evident, in contrast to experimental reports. The manuscript is accepted for publication at J. Mater. Res.

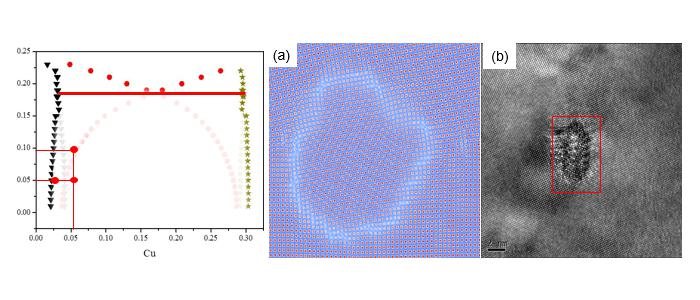

1.4 Microstructural Determination

Formation of β" precipitates in a high number density is desirable for the Al-Mg-Si alloys to obtain good mechanical strength and corrosion resistance, since β" is the major strengthening precipitate.The atomistic structure of β" in the ternary Al-Mg-Si alloys was constructed by Zandbergenand Andersen et al. [32] based on high-resolution transmission electron microscopy (HRTEM) and electron diffraction analysis. Their Mg5Si6 model published in Sciencein 1997 is widely accepted.

The higher peak-aged hardness and faster precipitation kinetics associated with the addition of Cu raised much concern from scientists in many fields about Al-Mg-Sialloys recently. However, the atomistic structure of the β" precipitates in Cu-containing alloys, in particular, the information regarding the distributions of Cu and Al in the lattice of β", is not clear.

By high-angle annular dark-field scanning transmission electron microscopy,it has been observed in our research that Cu exist in the structures of β" and C. Cu atoms partially substituted for atoms in the Si3 column pairs and the Mg1 columns of the Cu-free β"-Mg5Si6 atomic model, and the substitution was preferential in one column of each Si3 column pair. An average β" composition of 28.6 at.% Al-38.7 at.% Mg-26.5 at.% Si- 5.17 at.% Cu was measured by 3DAP,revealing that the Mg1 and Si3 sites in the β" are mainly substituted by Al and Cu. This finding provides significant guidance in designing the compositions of Al-Mg-Si-Cu alloys. The results have been published in Scripta Mater., a well-known journal in the materials community.

1.5 Phase-field Modeling & Microstructure Evolution Simulation

Phase-field method has become an important and extremely versatile technique for simulating microstructure evolution at the mesoscale for the past decades. By coupling to the reliable CALPHAD(CALculation of PHAse Diagram) thermodynamic and atomic mobility databases, two-/three-dimensional quantitative phase-field simulations of microstructure evolution in the target alloys during various phase transformation processes become feasible. Different examples, including solidification process in commercial Al alloys, spinodal decomposition in Ag-Cu alloys, aging process in Ni-based super alloys, and interdiffusion process of Ni-Al-Cr bond coat/substrate systems during service, are presented here for a vivid demonstration of the powerful phase-field simulation. The reproduction of microstructure evolution during various materials processes can provide thorough guidance for material design and industrial production. The reseach results have been published in Acta Mater., Metall. Mater. Trans. A, etc.

1.6 Cemented Carbides

TaC, as grain growth inhibitor, can improve the resistance to plastic deformation and high-temperature performance. Such an improvement is generally attributed to the excellent high-temperature hardness and thermal shock resistance. However, When the amount of added TaC is above the saturation solubility, dissolved TaC separates out mainly as brittle honeycombed (Ta,W)C cubic solid solution during the cooling process following liquid sintering temperature. The segregation of (Ta,W)C cubic phase leads to the inhomogeneousmicrostructure and deteriorates the mechanical properties of the cemented carbides. Thus, the improvement of the dispersity of (Ta,W)C solid solution in ultra-fine cemented carbides has become the big problem in industrial field.

Based on a combination of thermodynamic calculations and experimental work, we develop a new approach to control the segregation of (Ta,W)C cubic phase in cemented carbides. With the significantimprovement of the segregation, a dramatically improved combination of hardnessand transverse rupture strength of materials was obtained.Prior to experiment, thermodynamic calculations are performed with a desire to select the optimal alloy composition and sintering temperature. For that purpose, the phase diagram and mole percent of undissolved(Ta, W)Cat 1410 °C, as shown in Fig. 6, are computed using Thermo-Calcpackagebased on the thermodynamic database CSUTDCC1 established by our group. Based on the above calculations, threeWC–10Co–0.5Ta cemented carbides with different C content were preparedusing our new equipmentpurchased in this year.The microstructures and orientation of (Ta, W)C cubicphase analysis in samples were investigated using electron back scattered diffraction (EBSD) analysis. As shown in Fig. 7, the segregation of (Ta, W)C cubic phase can be significantly improved with the increase of the carbon content.Themechanism of segregation of (Ta,W)C cubic phase can be explained by the orientation of the fcc phaseand thermodynamic calculations.During cooling from the sintering temperature, dissolved Taatoms precipitate from theoversaturated binder phase on the amount of presently undissolved cubic phase or nucleation.The mole percent of cubic phase at the sintering temperature is important for the nucleation and grain growth of cubic phase. Both transverse rupture strength and hardness increase with the improvement of segregation in cemented carbides, as shown in Fig. 8. Using this method, the homogeneity of microstructure in the type of cemented carbides containing cubic phase can be controlled effectively. Our results have been published in Scripta Mater., a well-known journal in the materials community.

1.7 Hard Coatings

Recently, the introduction of multilayer structuration in TiAlN coatings have attracts extensive interest. Multilayer architecture with alternating deposition of two different nano-scale materials layer improves the fracture toughness of coatings by hinder or deflect crack propagation. Besides, outstanding mechanical properties such as extreme hardness and good wear resistance have been reported. Nevertheless, the periodicity of coatings (modulation period and modulation ratio) is a crucial factor responsible for the enhanced performance. To obtain the coherent growth in TiAlN/ZrN, first-principle calculations were employed to study the stability of coherent interface with various layer thickness ratio (tTiAlN : tZrN = 4:1, 3:2, 2:3 and 1:4). TiAlN(001)//ZrN(001) with tTiAlN:tZrN of 1:4 reveals lower total energy (ΔEmix) and higher work of separation(Wsep) than other configurations, therefore promoting the formation of coherent interfaces in multilayer. Furthermore, the TiAlN/ZrN multilayers with dissimilar modulation ration were deposited using cathodic arc evaporation by rotation of substrate holder. Structure determinations by XRD and TEM suggest that the epitaxial growth is achieved in TiAlN/ZrN coating with tTiAlN : tZrN of ~1:4, and the corresponding hardness value reaches to maximum of ~33.3 GPa. With the increase in thickness of TiAlN sublayers, the epitaxial growth is interrupted resulting in nanograin structure with lower hardness. This paper has been submitted to Scripta Materialia for publicaiton.